Repair

Repair

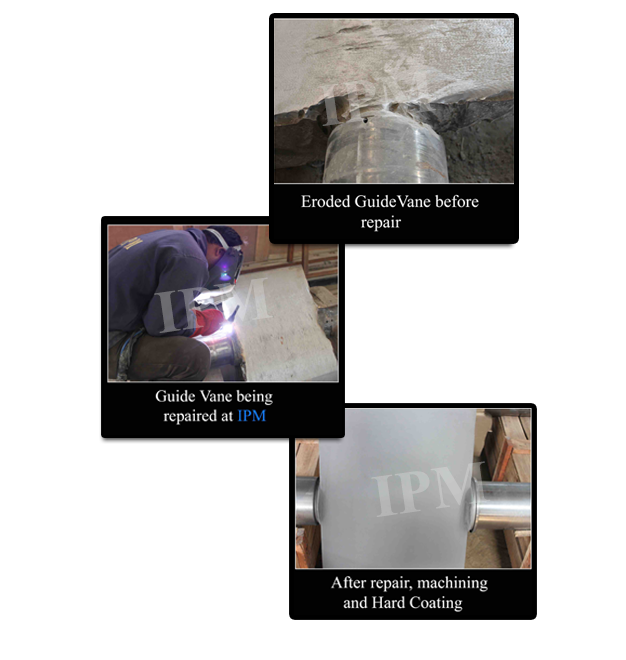

IPM, offers highly specialized repair & reclamation service for worn-out and miss-machined components. A vast experience in the field of repair & rebuilding enables IPM to take up more complex and challenging jobs. Regular updating of technology has made IPM an acknowledged leader in the field.

Each component coming in for repair at IPM under goes comprehensive NDT to ensure that all internal defects are identified and suitable repair strategy is formulated before start of repair. The detailed repair procedure and a suitable quality assurance plan is discussed and finalized with the customer. Engineers at IPM ensure strict compliance to the approved repair procedure & QAP through inprocess inspection & parameter control. After weld built components are machine on latest imported machines ensuring the highest degree of accuracy.

During grinding, templets are used for ensuring that accurate profile of runner blades & guide vanes are maintained, as per drawing. There after IPM provides a hard erosion resistant coating on the surface of the repaired components.

All major under water hydro-turbine components are being repaired & coated by IPM, including Pelton runners, nozzles, needle tips, needle tip liners, Francis runners, Kaplan runners, wicket gates, cheek plates, wear ring and labyrinths etc.

IPM also offers the following auxiliary services:

- Rebuilding

- Straightening

- Stress relieving

- Dynamic balancing

- Precision machining

- Grinding and super- finishing