What makes IPM a leader

IPM is an acknowledged leader- a one stop shop for all industrial surface modification and manufacturing needs. Being one of the oldest companies in India in this niche area, with IPM you can be sure that your project is in safe hands.

COMPREHENSIVE INFRASTRUCTURE FACILITIES

Our in-house infrastructure facilities are designed to cater to all needs, these include:

- Material handling facility up to 100 ton.

- Roof Height of 17 meters for overturning large components

- Turntable of 60 tons capacity, synchronized with the Robots

- Computerized monitoring system for monitoring the in-flight particle velocity & particle temperature.

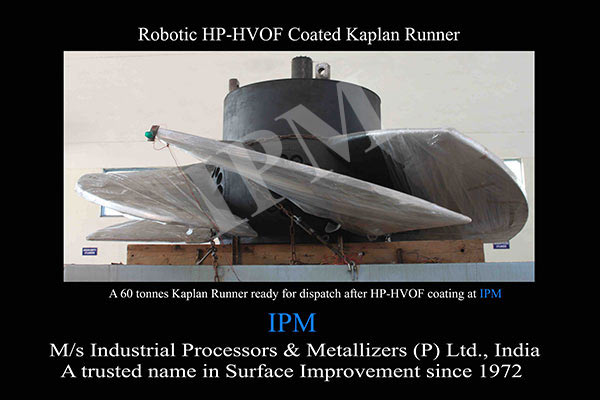

- Special coordinated motion robots and other accessories to carryout complete coating in difficult to reach areas of the underwater components including Francis Runners

OUR EXPERIENCE

With over four decades of unmatched experience IPM is known for its commitment to excellence. IPM has advanced Robotic coating facility backed by in-house R&D and comprehensive testing facilities. IPM has brought together a unique combination of experience, infrastructure, skill and dedicated teamwork.

Our team has practical experience of handling large sized industrial components up to 8 meters in diameter, 11 meters in length and weighing up to 100 Ton.

The exceptional performance record of the components surface modified at IPM speaks volumes about how dedicated we are to delivering quality.

EFFICIENT PROJECT MANAGEMENT

At IPM you are with a team of highly experienced engineers, each committed to the success of your project. IPM’s expertise in Project Management ensures fast turnaround time in order to minimize the down time of your component. The manufacturing, repair & coating procedure for each component is finalized after extensive study & brain-storming by experts. The process is documented using latest visual process mapping techniques and advanced softwares are used to minimize the time taken to execute each project.

STRINGENT QUALITY CONTROL

For each project, the Quality Assurance Department at IPM prepares a specific Quality Assurance Plan (QAP), with due approval of the customer. The Quality Assurance Department ensures that the QAP has all the required checks built-in. The Quality Control Department ensures that the QAP is strictly adhered to by the Production Department by conducting in-process inspections at each stage.

COMPREHENSIVE IN-HOUSE TESTING FACILITY

IPM has a well-equipped, in-house metallurgical lab to measure the following properties:

- Porosity

- Bond strength

- Online Particle Velocity measurement

- Hardness

- Micro-Structure

- Online Particle Temperature Measurement

- Thickness

- Surface roughness